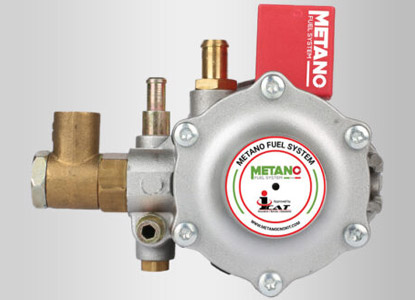

CNG Sequential Reducer is a main component in vehicles powered by Compressed Natural Gas (CNG) it is responsible for reducing the high pressure of gas from the tank to a level that is suitable for the engine. As part of sequential injection it ensures that CNG should be delivered to every cylinder in correct order, it helps in promoting combustion for better performance and fuel economy. By lowering the gas pressure from over 200 bar to approximately 1-2 bar, the sequential reducer ensures a consistent and controlled fuel flow. This enhances both engine efficiency and overall fuel savings.This pressure reduction happens in one or more stages and is carefully controlled to match the engine demand. Working in sync with the vehicle electronic control unit (ECU), the reducer ensures that each cylinder receives the right amount of gas at the right time. It also helps regulate the temperature and flow of the gas, improving engine performance, fuel efficiency, and reducing emissions, making it an essential part of clean fuel technology.Additionally, the reducer plays a crucial role in vehicles with dual-fuel systems, enabling smooth transitions between CNG and gasoline. As our CNG Sequential Reducer is made up of Durable Material , it helps protect the engine from wear and tear, extending the lifespan of both the engine and the CNG system. Equipped with safety features to prevent leaks and ensure secure operation, the CNG sequential reducer is essential for maintaining the safe, efficient, and reliable functioning of CNG-powered vehicles.

CNG Sequential Reducer is a main component in vehicles powered by Compressed Natural Gas (CNG) it is responsible for reducing the high pressure of gas from the tank to a level that is suitable for the engine. As part of sequential injection it ensures that CNG should be delivered to every cylinder in correct order, it helps in promoting combustion for better performance and fuel economy. By lowering the gas pressure from over 200 bar to approximately 1-2 bar, the sequential reducer ensures a consistent and controlled fuel flow. This enhances both engine efficiency and overall fuel savings.This pressure reduction happens in one or more stages and is carefully controlled to match the engine demand. Working in sync with the vehicle electronic control unit (ECU), the reducer ensures that each cylinder receives the right amount of gas at the right time. It also helps regulate the temperature and flow of the gas, improving engine performance, fuel efficiency, and reducing emissions, making it an essential part of clean fuel technology.Additionally, the reducer plays a crucial role in vehicles with dual-fuel systems, enabling smooth transitions between CNG and gasoline. As our CNG Sequential Reducer is made up of Durable Material , it helps protect the engine from wear and tear, extending the lifespan of both the engine and the CNG system. Equipped with safety features to prevent leaks and ensure secure operation, the CNG sequential reducer is essential for maintaining the safe, efficient, and reliable functioning of CNG-powered vehicles.

CNG sequential reducers offer several key advantages that enhance the performance and efficiency of CNG fuel systems. They ensure precise pressure regulation, reducing high-pressure gas from the storage tank to a safe, consistent level for engine use. This helps in achieving smooth and reliable engine performance, especially in vehicles with sequential injection systems. By delivering the exact amount of gas needed per cylinder, they contribute to improved fuel efficiency and lower emissions, making the vehicle more environmentally friendly. These reducers also help maintain stable gas temperature and flow, which protects engine components and extends their lifespan. Additionally, they support better throttle response, quieter operation, and seamless switching between petrol and CNG in dual-fuel systems. Their compact design and compatibility with a wide range of vehicles make them a practical and efficient choice for modern CNG-powered engines.

CNG sequential reducers play a vital role in ensuring the safe, efficient, and smooth operation of CNG-powered vehicles.