GEON takes a multi-disciplinary approach and provides a complete range of services from concept development to commissioning of theEnergy Plants.Below given are the exact details of the supplies &services made by us:

SUPPLIES & SERVICES:

1.PROJECT PROFILE:

The project profile will provide details on project system requirements, techno-economic feasibility, technical specifications, analysis of investment, production costs, cash flow, and profitability. Every relevant aspect of the project has been included in the profile. All relevant snaps of the projects, plants, and equipment are also included.

2.FEASIBILITY ANALYSIS:

Based on the results of following analysis, the feasibility report shall be prepared to ascertain the technical feasibility and commercial viability of the project.

Project Background: To describe the project idea and major project parameters.To identify project promoters, financial possibilities and their role within the project.

Market and Plant capacity: To prepare the possible users industries supply and demand projections on international, zonal and country basis with special reference to major consumption zones.To assess the growth rate in demand and supply over a period of next 10 years and the consequent picture of surplus/shortage.

To determine production programme based on anticipated sales. To determine plant capacity based on demand and market analysis.

Materials and Inputs: To study the available data on all the raw materials like tapes etc., their sources of supply, mode of transportation and economics of procurement and to give material and energy balances of the project in order to assess the requirement of raw materials and utilities.

Location and site: To study the suitability of any proposed sites for the plant keeping in view the economics viability of raw materials, land, power, water and fuel, manpower, transport facilities, social infrastructure facilities, financial incentives, market, environment conditions, communication channels, etc.

Process: To evaluate the suitability of process for different products.To select the most optimized process for processing after due consideration of factors such as the available raw materials, equipment availability, capacity range, capital cost, energy requirements andTo give detailed description of process adopted.

Technology: To identify the sources of technology and to make complete arrangement of the foreign collaboration and agreements.

Technical concept: To recommend broad sizing of the major equipment and storage.To prepare a general layout of the plant and preliminary flowsheet based on the technical concept outlined above.

Plant organization and overhead costs: To assess the requirement of staff and workers at various levels for efficient running of the plant.To suggest a suitable organizational structure for the proposed plant.To determine overhead costs

Project implementation schedule: To prepare a bar chart for the project implementation.To enumerate the critical activities which would have a bearing on the realization of the schedule described above.

Financial and economic evaluation: To assess the total capital cost for the project through budgetary quotations and based on the technical concept discussed above.

To recommend a suitable financing pattern based on the understanding reached with the client.

To assess the total cost of production based on:

- Cost of raw materials and consumable

- Cost of utilities

- Cost of wages/salaries and plant overheads.

- Contribution to R & D fund and administrative expenses.

- Contingency provisions

To ascertain the project profitability based on the cost of production as arrived at earlier and the sales realization occurring from the project.To assess the financial viability of the project based on the internal rate of return on investment/equity, pay-back period, break-even point and liquidity limit.

To prepare cash flow statements including working capital estimates, pre-operative cost, source and application of funds and other financial resources.To conduct a sensitivity analysis on the break-even point.

3.DETAILED PROJECT REPORT:

A detailed report has to be prepared containing following details on the project:

General: Name, form of organization and other details; brief particulars of the project.

Promoters:Bio-data of the main promoters, brief write-up on other companies promoted by the promoters.

Particulars of the industrial concern:Brief history; list of subsidiaries; particulars of holding company; details of directors.

Particulars of the project: Details of the project in terms of the following:

Capacity:Specification of major products and by-products section-wise capacities for the major sections of the plant.

Process:Details of technical process, reason for choosing the particular process, copy of process flow charts with material balance, utilities and process parameters.

Technical arrangements:Technical arrangements made, write-up on the collaborator, copy of collaboration agreement, particulars of consultants.

Management:Proposed arrangements for executive management; particulars of proposed key technical, administrative and accounting personnel; proposed organization chart.

Location and land: Location of the plant, land requirement and the arrangements thereof, location advantages, particulars in respect of the land acquired/proposed to be acquired, location map, site plan.

Buildings:Arrangements for constructing the buildings, master plan, plan of buildings, particulars of architect.

Plant and machinery:Basis of selection of equipment, list of imported and indigenous plant and machinery along with detailed specifications, layout of the plant and machinery indicating the flow of material.

Raw materials: Requirement of raw materials, components, chemicals, arrangements made for obtaining the raw materials/chemicals.

Utilities:Details about power, details about water, lay out for water system, details for steam, lay out of the steam system, details for compressed air, fuel, etc., details for transport.

Effluents: Details of the nature of atmosphere, soil and water pollution and measures proposed for control of pollution.

Labour: Estimates of total requirements and availability of skilled and unskilled labour, plans for training of personnel, manpower development programme.

Schedule of implementation:Schedule of implementation showing the commencement and completion of the following: acquisition of land, development of land, civil works, placement of order and delivery at site of plant and machinery (imported and indigenous), arrangements for power, arrangements for water, erection of equipment, commissioning, procurement of raw material and chemicals, training of personnel, trail runs, and commercial production; PERT chart.

Cost of project:estimate of cost of the project under the following heads:

- Land and site development

- Buildings

- Plant and machinery

- Technical know how fees

- Expenses of foreign technicians and training of Indians technicians abroad.

- Miscellaneous fixed assets

- Preliminary and preoperative expenses

- Provision for contingencies

- Margin money for working capital

Means of financing: Means of financing envisaged divided as follows: Share capital, rupee loans, foreign currency loans.

Marketing and selling arrangements: Brief notes on the products, their major uses, scope of market, possible competition from substitute products, existing and futuredemand and supply of products, list of principal customers, selling arrangements made, proposed selling organization for direct sales, proposed selling agreements.

Profitability and cash flow: Estimates of cost of production and working results for the first ten years of operation, cash flow statement for company as whole for ten operating years, projected balance sheet for ten operating years, brake even capacity level.

4.ALL CLEARANCES INCLUDING SUBSIDY, POLLUTION CONTROL, AND LICENSE:

All necessary documentation for clearances/approvals necessary for the project and all other applications, write-ups, clarifications, etc., required by various authorities, at various stages of the project.

5.POWER PURCHASE AGREEMENT

We can identify potential customers and obtain short term / long term Power Purchase Agreements, wheeling arrangements, or long term selling agreements. We facilitate investors to enter into MoU / PPA.

6.PROJECT FINANCE:

Project Feasibility:

We take up pre-feasibility studies, techno-economic study, size study and detailed feasibility study. We do project formulation, cost benefit analysis and sensitivity analysis of projects with reference to variations in capital and operating cost, time and cost-over runs, changes in interest rates or exchange rates, escalation of material cost or product prices or overhead costs.

Financial Structure:

We work and plan meticulously every detail in financial structure including business valuation, risk analysis, investor and capital sourcing, debt financing and equity financing, equipment and raw material financing, etc. We work to suggest the most appropriate financial structure and matching financial institutions/agencies as per business needs and can negotiate with international development agencies, commercial banks, FIIs and others.

Financial Closure:

We prepare the applications for equity and debt financing, including preparation of project appraisal report, project pitch, due-diligence, formation of syndicate, preparation / review of responses to queries of financial institutions, preparation and conclusion of preliminary term sheet, appraisal formalities, negotiation of terms and conditions of pre-commitment and sanction, review of common loan and securitization agreement and fulfilment of pre-disbursement conditions.

7.BASIC KNOW-HOW AND DETAILED ENGINEERING & DESIGNING SERVICE

The Contractor shall be responsible for the development of the Executive Design for the Plants, in compliance with the Project Documents, the Technical Specifications and Prudent Industry Practices, and shall also be responsible for:

(a) Complete civil and structure design of the biogas plant with all relevant drawings.

(b) Electrical schemes.

(c) Lists and specifications for equipment, materials, Spare Parts and accessories.

(d) Operations and Maintenance Manuals and training;

(e) Major Equipment warranties up to the Facility Acceptance Date and O&M Terms;

(f) Quality control plan, (henceforth, Quality Assurance Plan or QAP);

(g) Any other document or certificate necessary to comply with the rules and requirements set forth under the Project Documents and as may be directed by the Competent Authority from time to time.

(h) The Contractor, while designing the power project, shall ensure that the Plants deliver the rated capacity.

We manage the basic development of P & I diagrams, plant layouts, equipment sizing, hazard studies, and optimization. We supply Basic Engineering, know-how, and Plant and machinery by following: Process Engineering, mechanical engineering, architecture, civil and structural engineering, utility engineering, Electrical engineering, Instrumentation engineering, piping engineering services, etc.

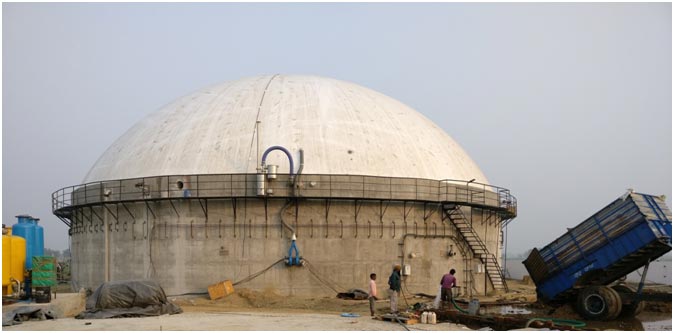

8.CIVIL CONSTRUCTION AND PLANT AND MACHINERY SUPPLY AND ERECTION

With emphasis laid on single-point responsibility, the company uses modern techniques for total construction management including selection of contractors, the material used and handling, store management, supervision, and monitoring of site progress till mechanical completion and pre commissioning checks.

9.PLANT OPERATION

We draw up an organizational plan, management structure, functional demarcation, and select & allocate proficient candidates for different jobs. We take up all types of services for efficiency improvement of operation of industrial assets: Marketing, Operational, Personnel, Technical & Purchasing Services.

10.ORGANIZATIONAL PLANNING AND PLACEMENT:

In terms of the project report and proposed implementation schedule, Consulting Engineers will assist the client in drawing up an organizational plan, management structure and functional demarcation areas.

In addition, Consulting Engineers will assist the client in sourcing, interviewing, evaluation and selection of candidates to man the various positions in terms of manpower requirements envisaged in the Project Report.

This part of Consulting Engineers work will be completed before the plant commences commercial production.

11.CARBON ACCOUNTING

Carbon Footprint & Strategy:

GEON helps to draw up strategies to measure and manage GHG emissions and use this intelligence to cut down your carbon footprint. The team focuses on the potential of integration to meet current challenges and future opportunities.

Carbon Offset Generation:

In CDM / VCS, we undertake projects in various disciplines including but not limited to: Renewable Energy (Bio Mass, Hydro Power, Wind Energy, Solar Energy), Waste Heat recovery, Cogeneration & Captive Power Projects, Fuel Switch Scenario, Captive Power Projects and Energy Efficiency Projects.

Our team offers full range of services, from strategy to solution implementation. We assist in project screening, due diligence, project origination & identification, preparation of Project Design Document (PDD, PCN/PIN). Under PDD preparation we will carry out the following tasks: establishing baseline, conduct environmental impact study, conduct the Monitoring & Verification Protocol, Conduct Stakeholder Consultation & address the comments thereupon. Host Country Approval (HCA from MoEF); facilitate Validation by a designated operational entity (DOE).

Offset Transaction Services:

Contracting for selling of CERs and VERs etc. Analysis and consulting to facilitate the creation of carbon credits from valid projects, aiding organizations to maximize commercial opportunities. Exclusive advisor to manage carbon assets; obtaining price bids, facilitating Emission Reduction Purchase Agreements (ERPAs).