Industrial Blowers

Industrial blowers are powerful devices used to move air or gases at high velocities for a variety of industrial applications. These blowers are crucial in providing efficient ventilation, cooling, and air circulation across manufacturing facilities, processing plants, and other large-scale industrial operations. With robust construction and advanced design, industrial blowers are optimized for both heavy-duty performance and energy efficiency.

Types of Industrial Blowers

-

Centrifugal Blowers

-

Design: These blowers use centrifugal force to increase the speed of the air and then direct it into a discharge pipe or duct. Centrifugal blowers are ideal for applications requiring high-pressure air.

-

Applications: Ventilation systems, pneumatic conveying, air handling units, and dust collection systems.

-

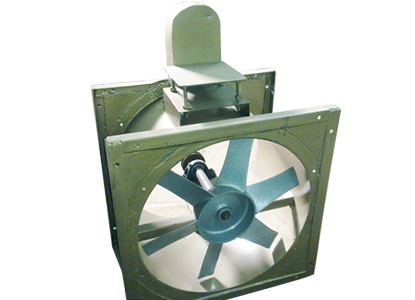

Axial Flow Blowers

-

Design: Axial blowers move air or gases along the axis of the fan. These blowers are typically used in situations where high airflow is required at lower pressure.

-

Applications: Cooling towers, HVAC systems, and large industrial facilities needing high volumes of air circulation.

-

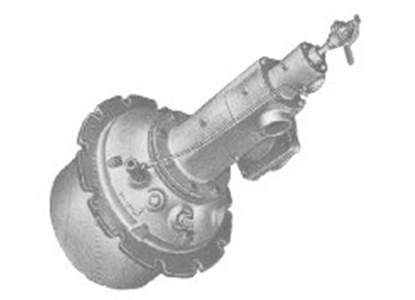

Positive Displacement Blowers

-

Design: These blowers trap a specific volume of air or gas and then discharge it. They provide consistent, continuous airflow and are often used for higher pressure systems.

-

Applications: Wastewater treatment plants, pneumatic conveying, and industrial dryers.

-

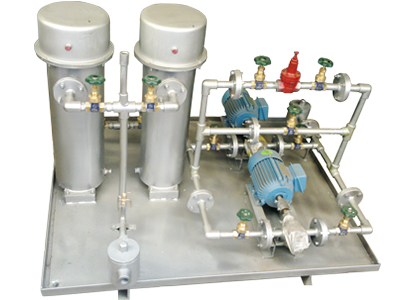

Regenerative Blowers

-

Design: A regenerative blower uses an impeller to move air in a series of stages, increasing both the volume and pressure. These blowers are known for their efficiency and quiet operation.

-

Applications: Vacuum systems, aeration in wastewater treatment, and material handling.

Key Features of Industrial Blowers

-

High Performance: Engineered for high airflow rates and pressure to meet the demanding needs of industrial applications.

-

Durable Construction: Made with heavy-duty materials such as stainless steel or cast iron to withstand harsh working conditions.

-

Energy Efficiency: Designed to operate at optimal energy usage, reducing operational costs over time.

-

Versatility: Can be used in various industries such as chemical, cement, food processing, power plants, pharmaceuticals, and more.

-

Customizable: Available in various sizes and configurations to meet specific air handling needs and space constraints.

Applications

Industrial blowers are used across various industries for applications that require airflow, pressure, or both. Common applications include:

-

Ventilation Systems: To ensure the safe circulation of air in hazardous environments or large facilities.

-

Dust and Fume Extraction: For collecting dust, fumes, and gases in manufacturing and chemical plants.

-

Cooling Systems: In power plants, HVAC systems, and industrial machinery cooling.

-

Pneumatic Conveying: Transporting bulk materials like powders, grains, or pellets through pipelines.

-

Wastewater Treatment: For aeration and oxygenation in treatment plants to ensure proper water treatment.

Benefits of Industrial Blowers

-

Improved Airflow Efficiency: These blowers provide consistent airflow, ensuring processes run smoothly without disruptions due to poor ventilation.

-

Cost-Effective Operation: With energy-efficient models, industrial blowers help reduce electricity usage, cutting down on operational costs.

-

Long-Term Durability: Built for long-lasting performance, reducing the need for frequent maintenance and replacements.

-

Easy Maintenance: Designed for simple maintenance with replaceable parts like filters, fans, and bearings.

Conclusion

Industrial blowers are indispensable tools in a wide range of industries. Whether it’s for ventilation, cooling, or air filtration, these blowers ensure that industrial processes run efficiently and safely. By selecting the right type of blower for specific applications, businesses can optimize performance, reduce costs, and improve overall operational efficiency.

|

|

|

|

| V-Belt Drive |

Standard Duty Fan |

Standard Duty Fan |

Double Stage Blower |

| WG Pressure in Inches |

1" |

2" |

3" |

4" |

6" |

8" |

10" |

12" |

16" |

20" |

24" |

28" |

32" |

36" |

42" |

48" |

56" |

| Motor H.P |

APPROXIMATE CAPACITIES IN CUBIC FEET PER MINUTE AT N.T.P. |

| 1/4 |

750 |

400 |

... |

... |

... |

... |

... |

... |

... |

... |

... |

... |

... |

... |

... |

... |

... |

| 1/2 |

1500 |

800 |

500 |

400 |

... |

... |

... |

... |

... |

... |

... |

... |

... |

... |

... |

... |

... |

| 1 |

3000 |

1600 |

1000 |

800 |

675 |

300 |

250 |

225 |

150 |

... |

... |

... |

... |

... |

... |

... |

... |

| 2 |

6000 |

3200 |

2100 |

1600 |

1000 |

650 |

525 |

460 |

340 |

280 |

... |

... |

... |

... |

... |

... |

... |

| 3 |

8000 |

4800 |

3140 |

2400 |

1500 |

1280 |

1000 |

765 |

530 |

420 |

320 |

250 |

... |

... |

... |

... |

... |

| 5 |

11500 |

7350 |

5150 |

4000 |

3000 |

1800 |

1600 |

1350 |

900 |

720 |

600 |

500 |

400 |

... |

... |

... |

... |

| 7.5 |

14500 |

10250 |

7500 |

5500 |

4000 |

3000 |

2550 |

2000 |

1490 |

1080 |

900 |

850 |

720 |

650 |

550 |

500 |

... |

| 10 |

20000 |

13400 |

9750 |

7750 |

5250 |

4000 |

3250 |

2900 |

2000 |

1575 |

1300 |

1175 |

1000 |

925 |

820 |

750 |

... |

| 12.5 |

27500 |

17000 |

12500 |

9750 |

6750 |

5100 |

4300 |

3575 |

2475 |

1970 |

1640 |

1400 |

1230 |

1150 |

900 |

825 |

... |

| 15 |

33000 |

20000 |

15250 |

12000 |

8250 |

6250 |

5500 |

4300 |

3100 |

2370 |

2025 |

1700 |

1550 |

1400 |

1080 |

900 |

... |

| 20 |

45000 |

26000 |

19500 |

15400 |

11000 |

7500 |

6800 |

5500 |

4320 |

3350 |

2700 |

2400 |

2100 |

1850 |

1440 |

1150 |

1000 |

| 25 |

... |

... |

... |

... |

12500 |

8750 |

8500 |

7200 |

5400 |

4250 |

3375 |

3000 |

2550 |

2325 |

1800 |

1250 |

1050 |

| 30 |

... |

... |

... |

... |

... |

10500 |

9500 |

8500 |

6500 |

5200 |

4050 |

3500 |

3175 |

2800 |

2250 |

1800 |

1500 |

| 40 |

... |

... |

... |

... |

... |

... |

11200 |

10500 |

7800 |

6500 |

5200 |

4400 |

3850 |

3300 |

2800 |

2250 |

1900 |

| 50 |

... |

... |

... |

... |

... |

... |

... |

12200 |

9500 |

8000 |

6750 |

5900 |

5250 |

4600 |

3700 |

3000 |

2450 |

| 60 |

... |

... |

... |

... |

... |

... |

... |

... |

11000 |

9300 |

7900 |

6600 |

6000 |

5250 |

4350 |

3250 |

|

| 70 |

... |

... |

... |

... |

... |

... |

... |

... |

... |

10500 |

9000 |

7300 |

6250 |

5400 |

4675 |

|

|

| 80 |

... |

... |

... |

... |

... |

... |

... |

... |

... |

11750 |

9900 |

8300 |

7150 |

6200 |

5200 |

|

|

| 100 |

... |

... |

... |

... |

... |

... |

... |

... |

... |

15000 |

12200 |

10400 |

8900 |

7800 |

6500 |

|

|