Reach-In Cabinet Ovens

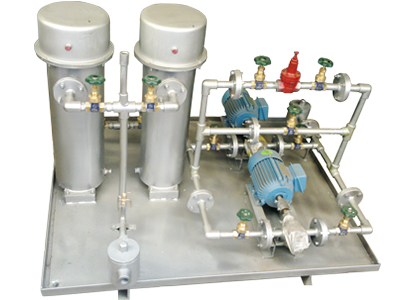

Champion SPI Industries offers a series of Reach-In Cabinet Ovens designed for a variety of industrial and laboratory applications. Available in four standard sizes and multiple models, these electrically heated ovens are built for reliability, efficiency, and ease of use. The Cabinet Batch (CB) series is capable of reaching temperatures up to 650°F and provides horizontal airflow through the work chamber, ensuring consistent temperature distribution.

Applications

These ovens are primarily used for:

Key Features

-

Airflow pressure switches on all blowers for efficient airflow regulation

-

Stainless steel interior for durability and ease of cleaning

-

6-inch thick, 6# density, semi-rigid batt insulation for excellent heat retention

-

Two shelves included for optimal use of interior space

-

Eurotherm 3216 digital temperature controller for precise temperature management

-

High limit controller for additional safety

-

Incoloy sheathed elements for high performance heating

-

Direct-driven recirculation blower, reducing maintenance by eliminating drive belts

-

Quiet operation for minimal noise disturbance

-

Energy-efficient design to reduce power consumption

-

480/3/60 power supply (alternative voltages available)

-

Compliance with FM, NFPA, and NEC standards

Available Options

-

Programmable controllers for advanced control over processes

-

Chart recorders for temperature and process data tracking

-

Timers for process downtime and startup

-

Main power disconnect switch for safety

-

Door limit switch for automated door operation

-

Powered exhaust blower for improved ventilation

-

Enclosure cooling fan for heat dissipation

-

PLC controls for automation

-

Data acquisition and recording for precise monitoring

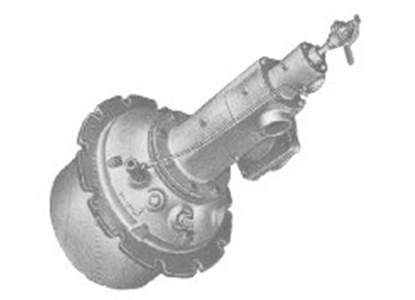

Elevator Style Ovens

Champion SPI Industries also manufactures Elevator Batch Ovens, offering a unique space-saving design while maintaining excellent temperature uniformity. These ovens are ideal for industries like aerospace, glass, and automotive, where space is limited, but high-efficiency heat treatment is required.

How It Works

The Elevator Oven design allows the load, often placed in baskets or on grids, to be lifted directly into the chamber using a lift mechanism. The oven doors, positioned at the bottom, close securely, and the heat treatment process begins. This design significantly reduces floor space requirements, making it a perfect solution for compact industrial environments.

Features

-

Electric, gas-fired, or indirect gas-fired heating options

-

Uniformity of ±5°F at operating temperatures of 540°C

-

Space-saving design that cuts floor space in half without compromising performance

These ovens are trusted for their reliable operation, compact design, and energy efficiency, and are widely used for heavy-duty heat treatment processes across a variety of industries.