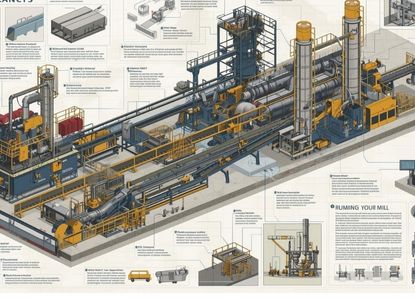

A Guide to Setting Up a Complete Tube Mill Plant

Establishing a new steel tube manufacturing facility is a complex undertaking that requires careful planning and the right technical partners. The most effective approach for new entrepreneurs is to collaborate with a specialized Tube Mill Plant Manufacturer India who can offer turnkey solutions. Unlike buying individual machines from different vendors a turnkey provider designs the entire plant layout ensuring that every component from the uncoiler to the packaging unit works in harmony. This integrated approach eliminates the compatibility issues that often arise when mixing machinery from various sources. The manufacturer analyzes the available floor space and the production goals of the client to create a workflow that minimizes material handling and maximizes efficiency. They also assist in selecting the right auxiliary equipment such as overhead cranes and cooling towers which are essential for smooth plant operations. This holistic support is invaluable for investors who may not have deep technical knowledge of the tube making process.

The heart of any such facility is the forming and welding line supplied by a competent Pipe and Tube Mill Machine Supplier. The process begins with the uncoiler feeding the steel strip into the accumulator which stores a buffer loop of material to allow for continuous operation while a new coil is being joined. The strip then passes through a series of forming rollers that gradually shape it into a cylinder. A good supplier ensures that these rollers are made from high grade tool steel to withstand the immense pressure and friction. Following the forming stage the edges are heated and fused together before the external bead is removed by a scarfing tool. The precision of these individual stations determines the quality of the final tube. A reliable supplier will always recommend equipment that balances initial cost with long term durability. They will also provide guidance on the maintenance schedules required to keep these heavy duty machines running at peak performance.

Financial planning is another critical aspect of setting up a plant and understanding the Tube Mills Price in India is essential. The cost of a tube mill plant varies significantly based on its production capacity and the level of automation. While it might be tempting to opt for the lowest priced machinery experienced industry players advise against compromising on build quality. A cheaper machine might use inferior components that lead to frequent breakdowns and high maintenance costs disrupting production schedules. It is wiser to invest in high quality equipment from a reputable Tube Mills Supplier in India that offers a better return on investment over its lifecycle. These suppliers often provide flexible payment terms and financing assistance to help businesses manage their cash flow. By making informed decisions and choosing the right manufacturing partner entrepreneurs can build a robust production facility that is capable of delivering high quality steel tubes for years to come.