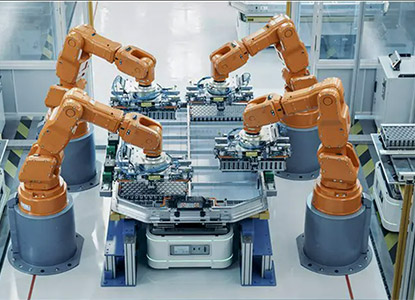

How Relays Improve Efficiency and Automation in Modern Factories

Modern factories rely heavily on automation to maintain speed, precision, and consistency. Relays play a crucial role in these systems by enabling safe, efficient, and intelligent control of machinery. Their reliability enhances overall productivity and reduces manual intervention.

- Enable Automated Machine Control: Relays allow machines to operate automatically by controlling electrical circuits, reducing manual effort while increasing the speed and consistency of industrial processes.

- Improve Energy Efficiency: By managing power flow efficiently, relays help reduce unnecessary energy consumption, lowering operational costs and improving the energy performance of automated systems.

- Protect Industrial Equipment: Relays prevent overloads, voltage spikes, and short circuits, ensuring machinery like motors and compressors operate safely and last longer.

- Enhance Production Accuracy: Automation relays ensure precise switching and timing, helping maintain accuracy in repetitive manufacturing tasks and reducing the chances of human error.

- Support Integration with Automation Systems: Relays act as a bridge between sensors, PLCs, and control units, enabling smooth communication and coordinated operation across factory automation networks.

- Reduce Factory Downtime: High-quality relays minimize equipment failures and unexpected shutdowns by ensuring stable circuit control, resulting in uninterrupted production cycles.

- Facilitate Remote Monitoring & Control: Modern relays allow integration with remote systems, enabling technicians to monitor, diagnose, and operate machinery without being physically present.