How to Choose the Best Millets Supplier in India

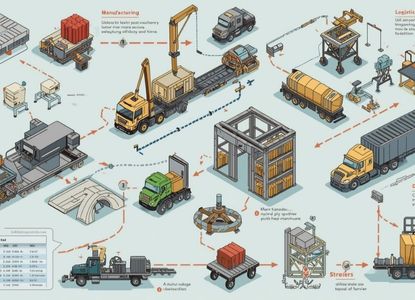

Choosing the right millet partner is a business decision, not a one-time purchase. A “best” supplier is the one who can deliver the same eating quality and cleanliness month after month, while keeping documentation, packing, and dispatch predictable. Start by defining your use-case: retail packs need great appearance and low impurities, while manufacturing needs consistent moisture and grind performance. Then shortlist suppliers who can share clear grade specifications, sample lots, and a standard process for cleaning, sorting, and packing. The goal is to reduce surprises price shocks, late trucks, mixed varieties, or inconsistent grain size. Once you evaluate the supplier like a system (procurement + processing + packaging + logistics), you can scale volumes confidently and protect your brand reputation.

What quality parameters should you check before buying?

Look beyond “looks clean” and ask for measurable parameters. Moisture is critical because higher moisture increases spoilage risk and reduces shelf life, especially in humid storage. Ask for the foreign matter percentage, broken grain tolerance, weeviled grain limits, and whether the lot is machine-cleaned and destoned. If you are health-positioning your brand, request pesticide residue testing where relevant and insist on batch-wise traceability. You should also confirm the variety and crop season foxtail, little millet, and barnyard can vary widely in grain size and cooking time. Finally, evaluate sensory quality: smell, color uniformity, and absence of mustiness. Good suppliers are comfortable putting these details in writing as specs.

How do you evaluate cleaning, sorting, and processing capability?

Processing capability decides consistency. Ask what steps they run: pre-cleaning, aspiration (light dust removal), destoning, grading by size, and final sorting. If the supplier claims “export quality,” ask what that means in their plant do they use color sorters, metal detectors, or at least magnetic traps? For millet flour, ask about grinding method, heat generation, mesh size, and how they prevent cross-contamination with other grains. Also check hygiene basics: covered storage, pest control, and separated raw vs. finished areas. If possible, request a short process video of the line running and packing. A supplier with stable systems can deliver repeatable output even when raw procurement varies across regions.

What documents and compliance should a supplier provide?

Documentation depends on your channel, but basics should be non-negotiable. For India-based food businesses, confirm the suppliers food safety registration and billing transparency. If you need lab testing, ask whether they can share COAs or help you test lots through NABL-accredited labs (you can also test independently). For larger B2B, request batch coding and inward/outward traceability records so issues can be isolated quickly. If you plan to export later, start building a compliance habit early: standardized packing lists, consistent labelling details, and clean lot identification. Reference: Food safety framework information is available via FSSAI (India).

How do packaging and labeling affect shelf life and returns?

Packaging is quality protection. Millets can absorb moisture and odors, so food-grade inner liners and moisture-resistant outer bags reduce spoilage and customer complaints. Ask the supplier what pack formats they support: bulk PP bags, laminated pouches, zipper packs, or vacuum options for premium retail. Confirm whether they print batch number, packing date, and best-before, and whether inks and adhesives are food-safe where applicable. For e-commerce, durability matters weak seals lead to leakage and returns. Also clarify storage guidance on label: cool, dry place; keep away from sunlight; and after-opening instructions. A supplier who treats packaging as “part of quality” helps you reduce wastage, preserve taste, and maintain visual appeal on shelves.

How can you negotiate pricing without sacrificing quality?

Start with a clear spec and negotiate around volumes and predictability, not by pushing the supplier to cut corners. Ask for a tiered quote: different prices for different cleaning grades, pack sizes, and delivery terms. Align on payment terms that reward performance—e.g., trial order, then higher volume with stable monthly off-take. Consider seasonal procurement: prices can soften post-harvest, so plan stock-building when feasible. Also clarify what is included: testing, packing, stitching, palletization, local transport, and replacement policy for quality issues. The best negotiation outcome is a stable system supplier earns reasonable margin, you get consistent quality, and both sides reduce emergency costs due to last-minute buying.

What steps help build a long-term supplier relationship?

Treat the supplier like a partner and formalise expectations. Use a simple purchase spec sheet for each millet: variety, grade, moisture limit, foreign matter limit, packaging type, and labeling details. Agree on a sampling method and a complaint resolution process, including timelines and evidence needed. Share forecasts monthly or quarterly so the supplier can plan procurement and processing slots. If you do private label, lock artwork and carton specs early to avoid delays. Finally, track performance with basics: on-time delivery rate, rejection rate, and customer feedback. Over time, this creates a “quality rhythm” where both sides know what good looks like, and problems are solved with data instead of arguments.

Conclusion

The best millet supplier is the one who can meet your exact specification repeatedly through strong procurement, reliable processing, clean packaging, and predictable logistics. Build your decision on measurable parameters (moisture, foreign matter, grading), verify processing capability, and insist on basic documentation and traceability. Pricing matters, but the real cost is inconsistency: returns, spoilage, and lost trust. Start with a trial, set clear specs, and create a simple scorecard. When you choose well, you gain more than a vendor you gain stability in supply, better product quality, and room to grow your millet business confidently.