Precision Engineering for Industrial and Flatbed Applications

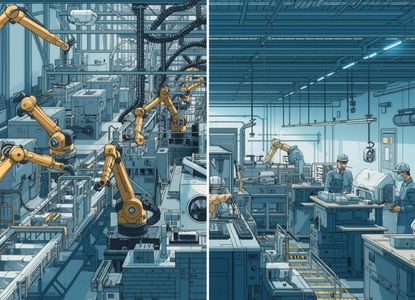

While the textile sector commands a large share of the market the application of screen printing extends far beyond fabrics into the realm of high precision industrial manufacturing. This niche is effectively served by the specialized Industrial Screen Printing Machine Supplier who provides heavy duty equipment designed for printing on rigid substrates like glass metal ceramics and printed circuit boards. Unlike the garment industry where the substrate is flexible and porous industrial applications require absolute stability and precise ink deposit control. This requirement has led to the development of robust flatbed systems by the leading Screen Printing Machinery Manufacturer. These machines are engineered with heavy cast iron frames and precision guide rails to ensure that there is zero vibration during the print stroke. This level of stability is non negotiable when printing conductive silver tracks on a membrane switch or intricate dial faces for automotive dashboards. Consequently finding a manufacturer with deep expertise in industrial applications is the first step for any business looking to produce high value technical parts.

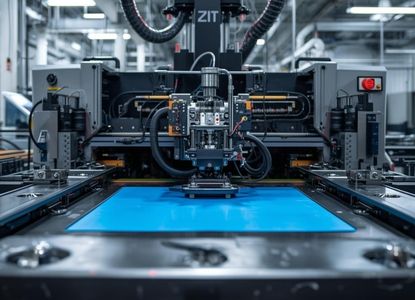

The core technology behind these industrial systems is the flatbed design which offers superior control over the printing process. A proficient Flatbed Screen Printing Machine Supplier ensures that their machines are equipped with powerful vacuum tables that hold the substrate firmly in place preventing any movement during the printing cycle. This feature is particularly important when printing on multi layered materials or when applying multiple passes of ink. The print head mechanism allows for micrometric adjustments enabling the operator to control the off contact distance and squeegee angle with extreme precision. Furthermore many industrial machines are now being integrated with UV curing bridges allowing the ink to be cured instantly as it leaves the print station. This integration streamlines the production line and eliminates the need for long drying racks saving valuable factory floor space. A specialized Screen Printing Machine Manufacturer will also offer customization options such as pop up pins for easy registration of irregular shapes ensuring that the machine is perfectly tailored to the specific production needs of the client.

Navigating the procurement of industrial screen printing assets involves a careful assessment of durability and serviceability. These machines are often required to run continuously in harsh industrial environments where dust and heat can affect performance. Therefore reliability is a key factor when choosing a supplier. A reputable Industrial Screen Printing Machine Supplier uses high grade components from trusted global brands to ensure the longevity of the equipment. They also provide comprehensive maintenance schedules and keep a stock of critical spare parts like pneumatic cylinders and vacuum pumps. This proactive approach to maintenance minimizes the risk of unexpected breakdowns. Additionally the supplier often acts as a process consultant helping the client optimize their ink formulations and screen mesh selection for specific industrial applications. By partnering with a supplier who understands the scientific nuances of industrial screen printing businesses can achieve consistent high quality results that meet the rigorous specifications of the automotive electronics and appliance industries.