Different Types of Creasing Machines and Their Applications

Creasing machines come in various types, each designed for specific materials and applications. Choosing the right type ensures efficiency, quality, and suitability for printing and packaging tasks.

- Manual Creasing Machines: Simple, cost-effective machines ideal for small-scale operations and occasional creasing of paper, cardstock, and light materials.

- Semi-Automatic Creasing Machines: Combine manual setup with motorized operation, suitable for medium-volume printing shops and consistent crease quality.

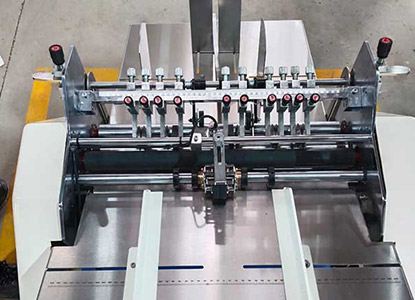

- Automatic Creasing Machines: Fully automated machines designed for high-volume production, ensuring speed, precision, and minimal operator intervention.

- Digital Creasing Machines: Integrated with digital printing workflows, these machines handle variable designs and short-run jobs efficiently with high precision.

- Rotary Creasing Machines: Use rotating dies to crease materials continuously, ideal for corrugated board, cartons, and packaging applications.

- Flat-Bed Creasing Machines: Provide flat-surface creasing, perfect for brochures, book covers, and thicker sheets requiring uniform pressure.

- Specialty & Custom Creasing Machines: Tailored for unique materials, shapes, or industrial requirements, offering flexibility for specialized printing and packaging projects.