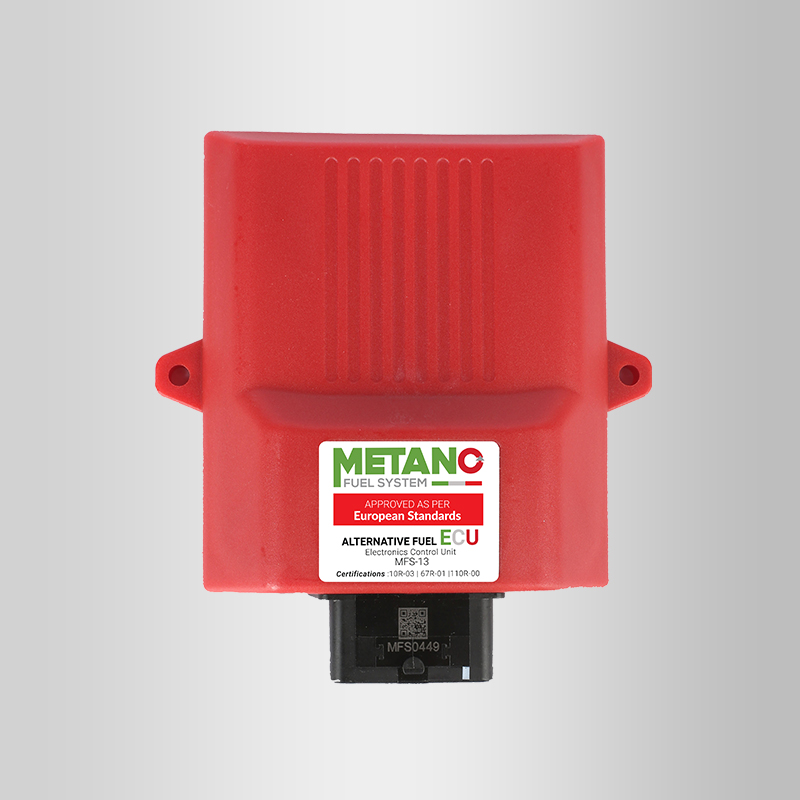

An Electronic Control Unit (ECU) model is a crucial component in modern vehicles, responsible for managing and controlling various electronic systems within the vehicle. It acts as the brain of the vehicle, processing inputs from sensors and making real-time adjustments to ensure optimal performance. In CNG vehicles, the ECU model specifically manages the fuel injection system, ensuring the correct amount of natural gas is delivered to the engine. It controls the sequential injection process, adjusts fuel pressure, monitors engine performance, and ensures smooth transitions between CNG and gasoline operation. The ECU model enhances efficiency, reduces emissions, and improves overall vehicle performance. Read More

An Electronic Control Unit (ECU) model is a crucial component in modern vehicles, responsible for managing and controlling various electronic systems within the vehicle. It acts as the brain of the vehicle, processing inputs from sensors and making real-time adjustments to ensure optimal performance. In CNG vehicles, the ECU model specifically manages the fuel injection system, ensuring the correct amount of natural gas is delivered to the engine. It controls the sequential injection process, adjusts fuel pressure, monitors engine performance, and ensures smooth transitions between CNG and gasoline operation. The ECU model enhances efficiency, reduces emissions, and improves overall vehicle performance. Read More

An injector is a critical component in both gasoline and CNG vehicles, responsible for delivering fuel into the engines combustion chamber. In CNG vehicles, the CNG injector precisely sprays compressed natural gas into the engine at the right time and in the correct amount for efficient combustion. This ensures optimal fuel efficiency, smooth engine performance, and reduced emissions. CNG injectors are typically controlled by the vehicles Electronic Control Unit (ECU), which adjusts fuel delivery based on engine demand. A properly functioning injector is essential for maintaining engine power, fuel economy, and the longevity of the vehicles fuel system. Read More

An injector is a critical component in both gasoline and CNG vehicles, responsible for delivering fuel into the engines combustion chamber. In CNG vehicles, the CNG injector precisely sprays compressed natural gas into the engine at the right time and in the correct amount for efficient combustion. This ensures optimal fuel efficiency, smooth engine performance, and reduced emissions. CNG injectors are typically controlled by the vehicles Electronic Control Unit (ECU), which adjusts fuel delivery based on engine demand. A properly functioning injector is essential for maintaining engine power, fuel economy, and the longevity of the vehicles fuel system. Read More

A CNG gauge is an essential device in CNG-powered vehicles, designed to measure the level of compressed natural gas in the fuel tank. It displays the remaining fuel, typically through a digital or analog readout, indicating when the vehicle needs to be refueled. The gauge works by monitoring the pressure inside the tank, as CNG is stored at high pressure, and this pressure decreases as fuel is consumed. The gauge helps drivers manage fuel consumption, avoid running out of gas unexpectedly, and maintain vehicle performance. In cities like Delhi, where CNG vehicles are common for their environmental benefits, a reliable CNG gauge is crucial for safety, efficiency, and optimal fuel usage. Read More

A CNG gauge is an essential device in CNG-powered vehicles, designed to measure the level of compressed natural gas in the fuel tank. It displays the remaining fuel, typically through a digital or analog readout, indicating when the vehicle needs to be refueled. The gauge works by monitoring the pressure inside the tank, as CNG is stored at high pressure, and this pressure decreases as fuel is consumed. The gauge helps drivers manage fuel consumption, avoid running out of gas unexpectedly, and maintain vehicle performance. In cities like Delhi, where CNG vehicles are common for their environmental benefits, a reliable CNG gauge is crucial for safety, efficiency, and optimal fuel usage. Read More

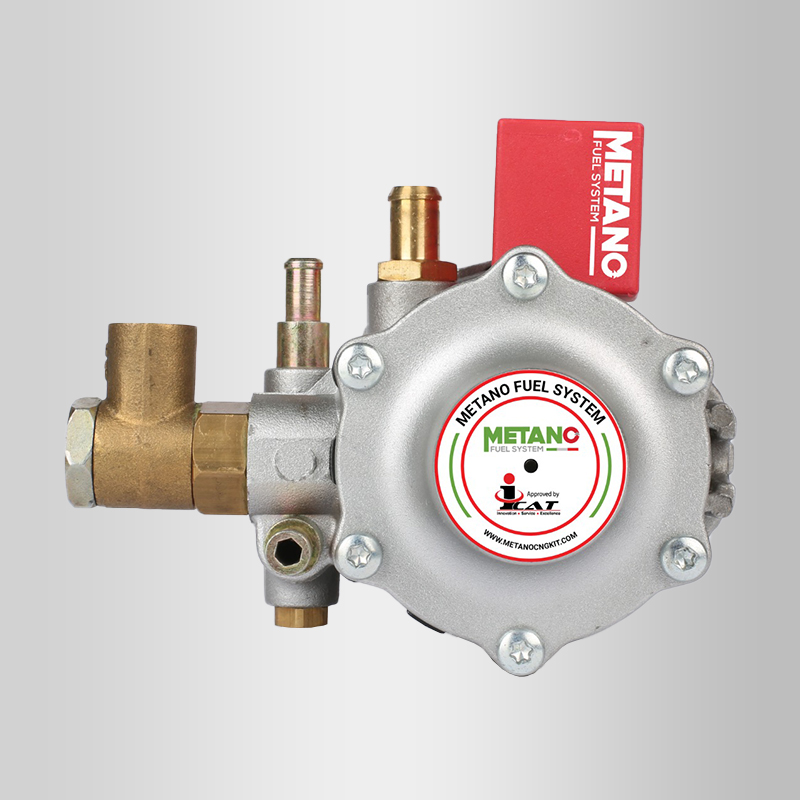

A filling valve is a vital component in the CNG (Compressed Natural Gas) fueling system, allowing the transfer of compressed natural gas from a refueling station into the vehicles fuel tank. Located on the CNG tank, the filling valve controls the flow of gas during refueling. It ensures a secure and safe connection between the vehicles fuel tank and the fueling stations hose, preventing leaks or accidents. The valve is equipped with a special mechanism that only allows gas to flow into the tank when the nozzle is properly attached. Additionally, the filling valve is designed to withstand the high pressures at which CNG is stored, ensuring that refueling is both efficient and safe. This component is crucial for maintaining the integrity of the CNG fuel system, preventing overfilling, and ensuring that the fuel tank is filled to the correct capacity. In places like Delhi, where CNG is widely used as an eco-friendly fuel alternative, a reliable filling valve is essential for safe and effective refueling. Read More

A filling valve is a vital component in the CNG (Compressed Natural Gas) fueling system, allowing the transfer of compressed natural gas from a refueling station into the vehicles fuel tank. Located on the CNG tank, the filling valve controls the flow of gas during refueling. It ensures a secure and safe connection between the vehicles fuel tank and the fueling stations hose, preventing leaks or accidents. The valve is equipped with a special mechanism that only allows gas to flow into the tank when the nozzle is properly attached. Additionally, the filling valve is designed to withstand the high pressures at which CNG is stored, ensuring that refueling is both efficient and safe. This component is crucial for maintaining the integrity of the CNG fuel system, preventing overfilling, and ensuring that the fuel tank is filled to the correct capacity. In places like Delhi, where CNG is widely used as an eco-friendly fuel alternative, a reliable filling valve is essential for safe and effective refueling. Read More

A CNG (Compressed Natural Gas) MAP sensor is a specialized variant of the Manifold Absolute Pressure sensor designed for vehicles running on CNG fuel systems. Its primary function is to measure the pressure in the intake manifold and monitor the flow of CNG into the combustion chamber, ensuring precise control of the air-fuel ratio. Unlike gasoline MAP sensors, the CNG MAP sensor is calibrated to handle the unique properties of natural gas, such as its lower energy density and different combustion characteristics. The data collected by the CNG MAP sensor is sent to the Engine Control Unit (ECU), which uses it to regulate the injection of CNG, ensuring optimal combustion efficiency, reduced emissions, and enhanced fuel economy. Additionally, the sensor helps monitor the switch between CNG and gasoline in bi-fuel vehicles, maintaining seamless operation. If the CNG MAP sensor fails or provides inaccurate readings, it can lead to issues like misfires, reduced power, poor mileage, and increased emissions. The sensors environment in CNG systems often exposes it to higher pressures and varying temperatures, requiring robust design and periodic maintenance. Advanced CNG MAP sensors are equipped to withstand these conditions while ensuring precise and reliable measurements, playing a crucial role in achieving the eco-friendly benefits and performance efficiency that make CNG a popular alternative fuel choice. Read More

A CNG (Compressed Natural Gas) MAP sensor is a specialized variant of the Manifold Absolute Pressure sensor designed for vehicles running on CNG fuel systems. Its primary function is to measure the pressure in the intake manifold and monitor the flow of CNG into the combustion chamber, ensuring precise control of the air-fuel ratio. Unlike gasoline MAP sensors, the CNG MAP sensor is calibrated to handle the unique properties of natural gas, such as its lower energy density and different combustion characteristics. The data collected by the CNG MAP sensor is sent to the Engine Control Unit (ECU), which uses it to regulate the injection of CNG, ensuring optimal combustion efficiency, reduced emissions, and enhanced fuel economy. Additionally, the sensor helps monitor the switch between CNG and gasoline in bi-fuel vehicles, maintaining seamless operation. If the CNG MAP sensor fails or provides inaccurate readings, it can lead to issues like misfires, reduced power, poor mileage, and increased emissions. The sensors environment in CNG systems often exposes it to higher pressures and varying temperatures, requiring robust design and periodic maintenance. Advanced CNG MAP sensors are equipped to withstand these conditions while ensuring precise and reliable measurements, playing a crucial role in achieving the eco-friendly benefits and performance efficiency that make CNG a popular alternative fuel choice. Read More